Handbook of Lean Manufacturing in the Food Industry. They allow you to organize facts, opinions, and issues into taxonomies in order to help diagnose complex problems and identify common issues.

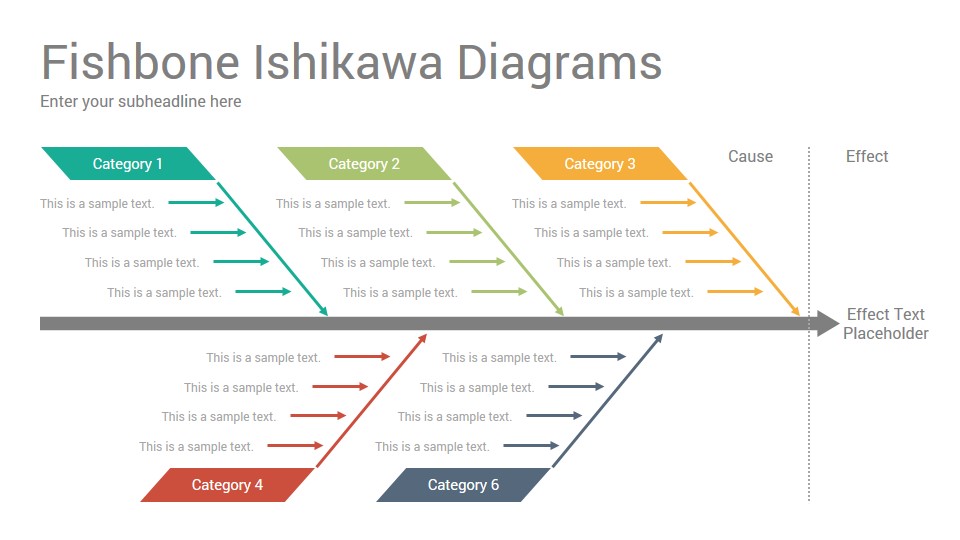

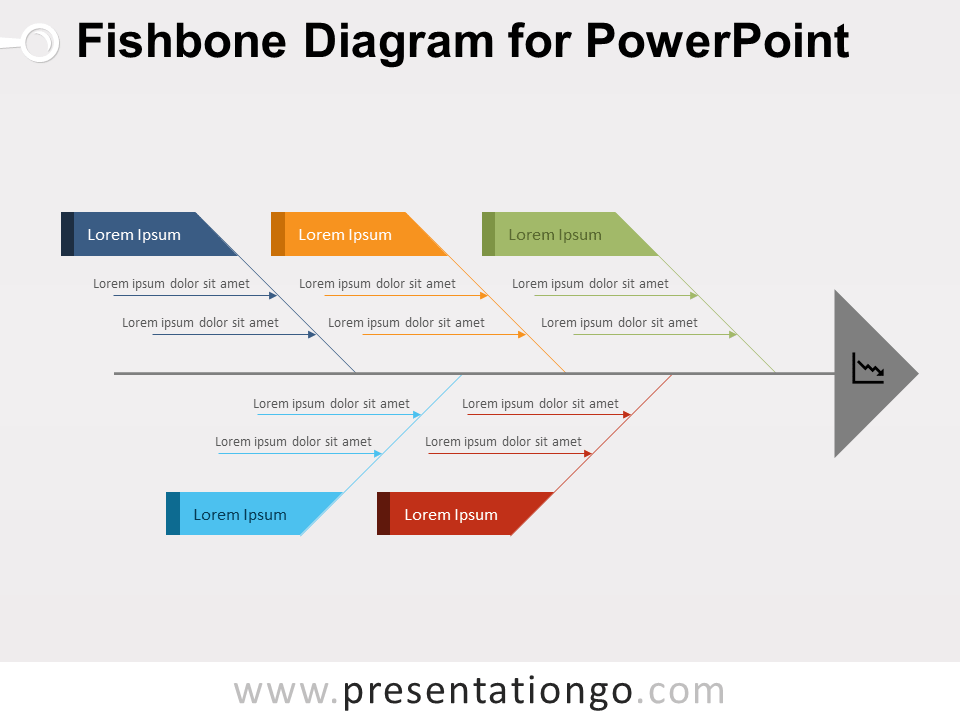

Reliability engineering : a life cycle approach. Failure mode and effects analysis (FMEAs) for small business owners and non-engineers : determining and preventing what can go wrong. ^ "Fishbone diagram: Solving problems properly".Improving complex systems today : proceedings of the 18th ISPE International Conference on Concurrent Engineering. Milwaukee, Wisconsin: American Society for Quality. By reviewing each potential cause in detail, teams can identify areas where they need to make changes and eliminate errors. As the diagram develops, focus efforts on areas of the chart where causes are thinīy the time a chart is completed, teams have many options on the root causes leading to the final, problematic outcome.It gets its name from the fact that the shape looks like a fish. Teams again ask, “Why does this happen,” this time breaking down the possible causes in each category even further The Fishbone Diagram is another name for the Ishikawa Diagram or Cause and Effect.Many of these lines come from asking the question: “Why does this happen?” Team members brainstorm all the possible causes within each category, writing them on branching lines from the main category lines.These typically fall into one of these areas: Methods, Machines, People, Materials, Measurement, Environment It also benefits the individual users by ensuring corrective actions. Companies can use it for cause and effect analysis and avoid employee burnout. It lets you identify the causes and threats that you may not see with bare eyes. On lines branching off this centerline, list the categories where the causes are likely occurring. An Ishikawa or Fishbone diagram is a visual approach for proactive risk controls.They write the statement on the center-right of the diagram, with a horizontal line running across to it Write a problem statement: This is the effect the team wants to change.Project teams should follow certain steps to ensure that they use a Fishbone Diagram properly. In Six Sigma, it’s used with an existing product or operation to identify and eliminate the causes of defects and errors. Today, the Fishbone Diagram is still frequently used in manufacturing and product development. Listening (the sound experience of the engine and wind while driving).Driving (ride stability, acceleration, etc.).Touch (the tactile experience of the car for drivers).Mazda famously took this approach in creating the Miata sports car (the MX5), detailing the six components that would make the final product. It is a way to brainstorm all potential causes of a problem.

The diagram is useful in product development, where project teams list all the factors that contribute to making a product and break them down into smaller components. A Fishbone Diagram (also referred to as Ishakawa Diagram) is a tool used for root cause analysis. The name Fishbone Diagram comes from the shape of the diagram, which when completed resembles the shape of a fish. Based on an idea for problem-solving developed earlier in the 20 th century, Ishikawa’s diagram because popular in the 1960s at Kawasaki. Ishikawa invented the Fishbone Diagram for the shipbuilding industry in Japan. The use of a Fishbone Diagram requires that a team look at all possible causes for errors and mistakes, not just those they have come up with in the past or that team members suspect is the root cause.īecause of its usefulness, a Fishbone Diagram is one of the most popular tools in Six Sigma. It’s also useful for teams who find that their thinking on solving a challenge has fallen into a rut. Another name for the diagram is the Cause and Effect Diagram or Ishikawa Diagram (named for the diagram’s inventor, Kaoru Ishikawa).Ī Fishbone Diagram is an effective tool for project teams tasked with finding the root causes of a problem. A Fishbone Diagram is a visual tool that allows project teams to easily display a list of potential causes of a problem, then break these causes down into increasingly more detailed components until a link is found between a root cause and the final outcome.

0 kommentar(er)

0 kommentar(er)